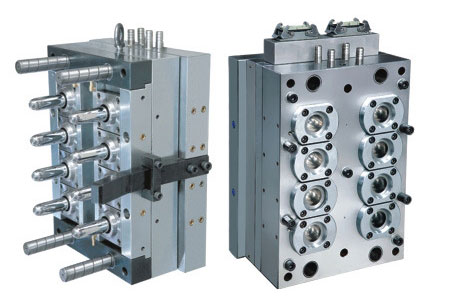

Germany heating elements high quality for longest mould lifetimeĭo you need any PET Preform mold? contact us to get a price. Improved valve gate system with interchangeable and durable melt PET material sealing PET Preform mold feature: Precision temperature controlling and even heating area for hot manifold PET Preform mold Steel: PET preform mold base steel: DIN1.2311 with precision grinding machine with each plate thickness tolerance 0.015mm for a plate size 500*500*40 with HRC32 PET preform mold spare steel: DIN1.2344 in D-M-E metric dimension standard all the moving area was inserted with durable parts which is interchangeable, hardness is HRC 48-52 PET preform mold cavity and core steel: S136 stainless steel, tempered with HRC50+/-2 Screw neck slide pieces: Inserted with prehardened DIN1.2316 with HRC38 to HRC42 Tell us you need and requirement, ST can offer you a tailor made PET Preform mold solution. ST has rich decades of year’s experience of PET bottle mold & PET Preform mold making. ST PET Preform mold has advanced valve gate system and cooling system, cap mold unscrewing ejection system and extrusion blowing mold auto deflashing system ST has strong PET Preform mold design capability with four design department. Annually, ST can offer international market around 150 sets of PET preform mold.

PET PREFORM MOLD PROFESSIONAL

Technologists professional in after-sales line and excellent credit assures stable operation of the machines.As a specialist in PET Preform mold Making, SINCERE TECH is devoted to offering our customers high quality PET Preform mold based on high quality mould steel, high quality mould design and high precision mold processing. The screw neck is made and inspected strictly by the standard of Coca cola and the screw neck has been up to the standard of Coca cola. Inspection tools include projector, hardness tester, stress tester, eccentric tester, electric balance and other inspection tools. The products of our preform are cover from :Water bottle, oil bottle. Offering temperature controller and voltage controller according to customers' requirement R&D and manufacturing of PET / PP Preform Moulds from 2 cavities to 144 cavities. Proces includes PET preforms preform cooling preform inspection coinjected preforms barrier preforms. This preform is then reheated, stretched and blown into its final shape. In the first step, PET is injection molded into a mini bottle complete with threads, called a preform. German intelligent temperature controller (PID continuous power controlling).ģ. Processing PET into bottles can take two steps. All of these increases processing precision, good interchangeability and low eccentricity ≤0.10mm (perform length≤100).Ģ. Many machine tools are imported from America and Japan, such as Machine center, CNC lathers, EDM and so on. German Vacuum stove is imported for heat treatment of the components, which assures the hardness of components HRC45-HRC48. plate method avoids corrosion efficaciously and assures long life service of the perform molds.ģ. The main components of perform molds are made of S136 material (Sweden ASSAB).Ģ. Reasonable- designed cold water channels increase cooling effect and shorten the cycle time.ġ. Advanced hot runner system assures lower level of AA value.ģ. The weight of the preforms is 15.5g, Cycle time is 28 Sec with general PET screw injection. No cutting of valve gate is employed to reduce the labor cost.Ģ. The PET preform mold is designed for SQ injection molding system. Xijie help customers develop new product and promote customers to be the pioneers. We also design cold parts, hot runners and other main exchangeable components to fix on the imported perform molds.ġ. What Xijie supplys is not only pet preform mould, but also suitable solution. At the same time we can manufacture pet perform molds especially according to customers' injection molding machines.

We supply special technology training and other good after-sales service.ĭemark has a powerful team for research and development, which is capable of manufacturing the pet perform molds with 1 cavity to 144 cavities including the pet preform injection molding system. Various kinds of processing equipment and detection measurement instrument are imported, as well as special drawing soft is applied in designing performs, samples and manufacturing testing mold. We invite many technical committee members and senior professors in mould line are as the technical consultants for our company. Demark, specialized in manufacturing 32, 48, 72 cavities PET Preform Mold, consists of technologists with rich experience, and senior engineers with master's degree and professional in 3D.

0 kommentar(er)

0 kommentar(er)